75# Ceramsite sand

Baozhu sand/precision casting sand is a kind of artificial environmental protection casting sand, which is made of high quality bauxite material and melted by electric arc furnace. After years of experiments, the baozhu sand produced by arc melting overcomes the shortcomings of traditional casting sand, and has the advantages of high temperature resistance, easy collapse, good grain shape, low crushing rate, and strong reusability. Cost far more than chrome ore, zircon sand, is the casting of carbon steel, alloy steel casting ideal molding materials and access to domestic and foreign casting experts recognized. The main chemical composition is AL2O3. The casting sand is close to standard spherical sand with an angle coefficient of 1.1. A good grain type greatly improves the air permeability of the casting mold and can greatly save the amount of binder (about 30% ~ 40%). The casting sand has a small expansion coefficient (1000 ℃-0.13), which can greatly improve the casting accuracy. Mohs hardness is 7.8, with high hardness, greatly reducing the crushing rate of sand, its recycling rate can reach 98%; Baozhu sand as a neutral material PH is 7.8, which is suitable for binders with various ingredients.

Classification:

Key words:

75# Ceramsite sand

Product Description

Baozhu sand/precision casting sand is a kind of artificial environmental protection casting sand, which is made of high quality bauxite material and melted by electric arc furnace. After years of experiments, the baozhu sand produced by arc melting overcomes the shortcomings of traditional casting sand, and has the advantages of high temperature resistance, easy collapse, good grain shape, low crushing rate, and strong reusability. Cost far more than chrome ore, zircon sand, is the casting of carbon steel, alloy steel casting ideal molding materials and access to domestic and foreign casting experts recognized. The main chemical composition is AL2O3. The casting sand is close to standard spherical sand with an angle coefficient of 1.1. A good grain type greatly improves the air permeability of the casting mold and can greatly save the amount of binder (about 30% ~ 40%). The casting sand has a small expansion coefficient (1000 ℃-0.13), which can greatly improve the casting accuracy. Mohs hardness is 7.8, with high hardness, greatly reducing the crushing rate of sand, its recycling rate can reach 98%; Baozhu sand as a neutral material PH is 7.8, which is suitable for binders with various ingredients.

The core of the regeneration process of casting sand is to remove the residual binder from the waste sand, minimize the adverse effects of the residual binder, realize the low emission of the casting process, and achieve recycling. Chromium sand, quartz sand due to their own characteristics, waste sand regeneration process, easy to powder, recycled sand burning reduction, binder to add a large amount, the use of increased costs, these will bring difficulties to the recycling.

The main components and performance indexes of jewel sand are as follows

- Al2O3 ≧ 70% Fe203 ≦ io2:2.5-3.5 SiO2: 8-12% Others: Trace

- Grain shape: spherical

- Color: Brown Black

- Angular coefficient: ≦ 1.1

- Density (dense packing):1.95-2.05(g/cm3)

- Refractoriness: 1850 ℃

- Thermal conductivity:(1000 ℃)0.196 W/m · K

- Accumulation specific gravity: 1.95-2.05 tons/m

- Mohs hardness: 7.5-7.8

Ceramsite sand is a neutral material, high fire resistance, chemical stability, resistance to acid and alkali erosion. PH:7.6, acid consumption value: 1.5mL/50g. Good grain shape, can save a lot of binder, so as to overcome a variety of casting defects. The company can provide 0.053mm-2.0mm range of various specifications of Ceramsite sand products, but also according to your company's situation, to provide technical services.

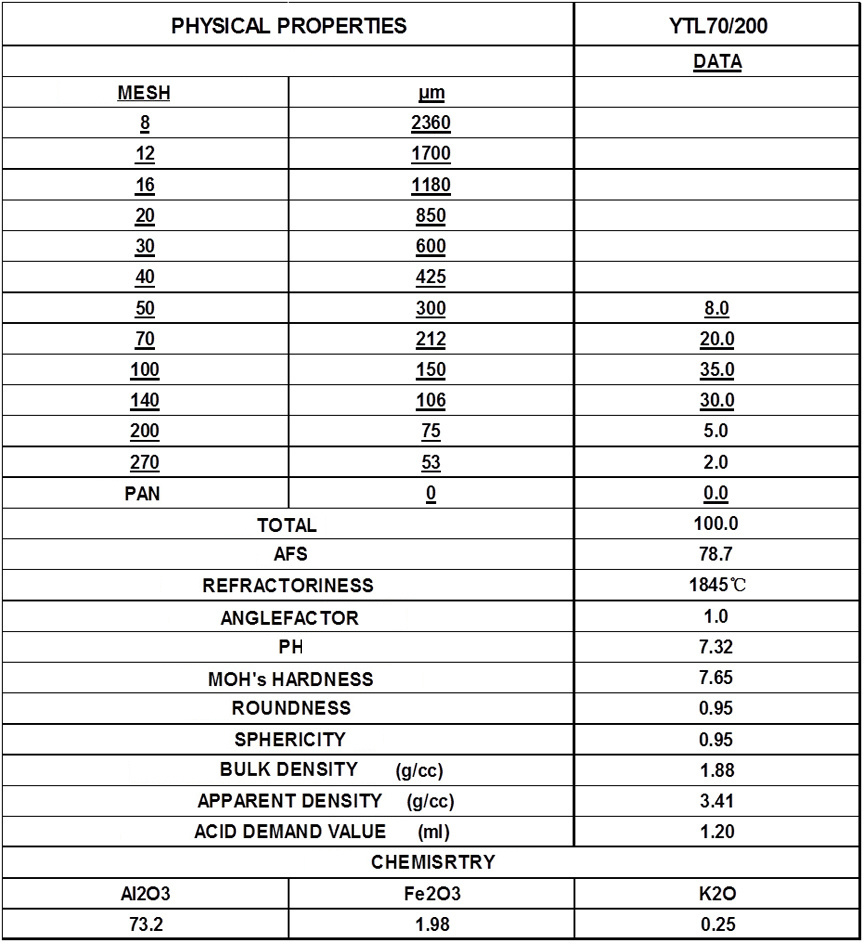

Product (Product Name): YTL70/200(AFS:75-85)

Previous Page

Next Page

Previous Page

Next Page

Related Products

Consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!